As the world is progressing, more people are researching on the ‘Green Building Index’ and are trying to figure out new ways of improving the methods of construction, in order to make the infrastructure more sustainable. Although, bricks are essential components of construction, not much focus has been paid towards their sustainability.

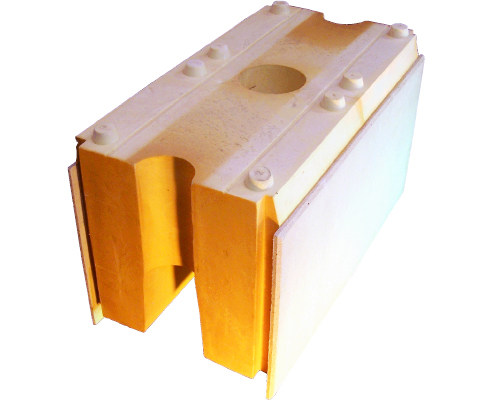

Keeping sustainability in mind, ‘Green Energy Bricks’ have been introduced in Australia. These bricks tackle all the key sustainability issues in contrast to conventional block masonry. The center of the brick is made of Polyisocyanurate Foam [1] while Magnesium Oxide (MgO) [2] films enclose both sides of it as shown in Figure 1. The foam makes the bricks light in weight and offers natural insulation whereas the MgO films toughen the block and provide protection against fire.

Figure 1 – Green Energy Brick details (Source: Energy Bricks AU)

GE Bricks offer many more advantages that are listed below:

- They do not require mortar and are fairly large in size.

- A single layer of block functions as a double brick wall.

- A standard clay brick weighs 2.7KG, whereas a green brick (more than double the size) weighs only 3.3KG. This difference is chiefly due to the fact that GE Bricks do not require mortar, thus reducing the weight of the entire structure quite significantly.

- These bricks are easy to install and require less labour.

- The foam inside the brick provides sufficient insulation making it more energy efficient.

Figure 3 – An 80mm hole provided in the centre of the brick allows easy electrical wiring (Source: Energy Brick AU)

Figure 2 – An 80mm hole provided in the centre of the brick allows easy electrical wiring (Source: Energy Brick AU)

[1] Polyisocyanurate: Also known as PIR, it is a thermoset plastic formed as foam for insulation. [2] Magnesium Oxide (MgO): A white solid consisting of Magnesium and Oxygen, mostly used as fertilizers and rubber.